19.03.25PI_602

BBG: Commissioning of a scientific test line for AI-based production automation

Research project of Helmut Schmidt University/University of the Federal Armed Forces in cooperation with BBG and Weidmüller

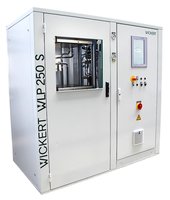

Mindelheim/Germany, 19 March 2025. BBG recently commissioned a scientific test line for industrial applications based on artificial intelligence (AI). In this project, the company demonstrates how AI is used in a production line for finishing automotive glass with polyurethane.

The Helmut Schmidt University/University of the Federal Armed Forces in Hamburg (HSU) is involved in the "EKI - Engineering für die KI-basierte Automation in Produktionsumgebungen" (Engineering for AI-based Automation in Production Environments) project. The research work is funded by dtec.bw - Zentrum für Digitalisierungs- und Technologieforschung der Bundeswehr (Center for Digitization and Technology Research of the German Armed Forces), which in turn is financed by the European Union - NextGenerationEU.

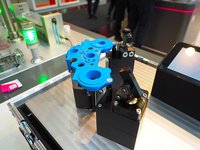

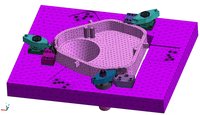

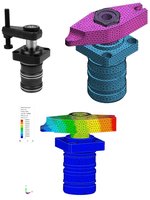

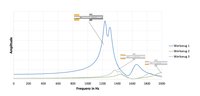

A fully automated production line for encapsulating glass panes with polyurethane (PUR) is used for the research project at BBG's headquarters in Mindelheim/Germany. The fully automated line includes three robots, several cameras for checking individual process steps, and more than 200 sensors for recording process data.

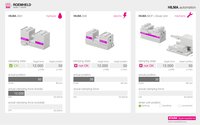

The process is divided into individual work steps and stations, each of which comes with its own decentralized control system, which in turn is connected to a central control system. Only the mold needs to be exchanged for a product changeover. Since this is detected via RFID, all settings and specifications are automatically adjusted for the production of the new product. This means that the line can be reliably converted at any time and within the shortest possible timeframe.

To download the complete press release and picture in print quality, please press next button.